What is a 3M VHB Tape?

The 3M VHB Tape is a two-sided adhesive tape produced by 3M. VHB stands for “Very High Bond”. As the name implies, it is a double sided tape with industrial strength. 3M has a catalog of VHB tapes that can suit different needs – from clear double-sided tapes to heavy-duty double-sided tapes for cars that are able to withstand extreme heat and cold.

This incredible piece of invention is also a popular solution for applications where aesthetics are important. With the adhesive tapes, you can do without the ugly screws or clamps that will alter the beauty of the product.

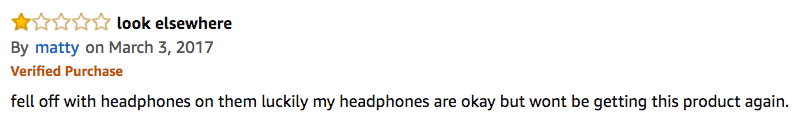

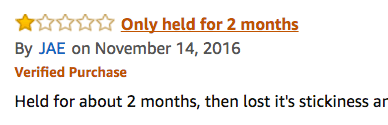

Headphone Stand Mount

In our context, the 3M VHB Tape is commonly seen on headphone stand mount. The headphone stand mount comes with a double-sided mounting tape that allows the headphone stand to be mounted on the undersides or sides of the table. Headphones owners who want a clean and easy way to keep away their headphone will choose the headphone stand mount over the usual headphone stand.

Pitfall

Although the 3M VHB Tape offers an aesthetically pleasing way to mount the headphone stand, you have to be stringent in the way you apply the 3M VHB Tape. Very often, negligence in the application procedure will result in the following complaint – the tape does not stick long enough.

As with most reviews on the internet, you only get to read one side of the story but it is clear that the 3M VHB Tape is no magic bullet. The good news is that you can greatly improve the adhesiveness of the 3M VHB Tape. We have compiled a step-by-step checklist for maximizing the strength of your 3M VHB Tape.

Checklist for achieving ultimate bond strength of the 3M VHB Tape

1. Preparing the surface

1.1 Make sure the surface is clean A rudimentary rule for good tape bond is checking the cleanliness of the surface that you will be applying it on. You should use rubbing alcohol to clean the surface. Make sure it is cleared of any specks of dirt and also the surface must be dry. If the surface is greasy, you will need a stronger solution like the 3M Citrus Base Cleaner to cut the oil. Finish off with the rubbing alcohol to ensure all residue are removed. 1.2 Add micro-abrasion When we add abrasion to the surface, we are increasing the surface area for additional adhesion. This is very effective for painted and plastic surface. The trick is to achieve micro abrasion and not deep cuts because the surface still needs to remain flat. You can use the Scotch-Brite® Hand Pads to achieve the right amount of abrasion. 1.3 Check texture of the surface Surfaces that are rough, porous or fibered are the worst to apply the 3M VHB Tape on. But if you insist on applying the tape onto them, you will need an extra step of preparation – sealing. This will help unify the surface to increase bond strength. Common sealing materials are paint, varnish and other hard surface coatings. You can also use Fast drying 3M™ Rubber and Vinyl Spray 80. 1.4 Check nature of the surface Hydrophilic(water-loving) Water-loving surface affects the adhesive bond durability in high humidity environment. The water vapor weaken the tape bond and the adhesion strength. Solution: Use rubbing alcohol solutions that comes with silane coupling agents to reduce the water-loving tendency of the surface. Examples of hydrophilic surfaces:

Glass Stone Ceramic

1.5 Oxidation Surfaces that are susceptible to oxidation will weaken the tape bond too. Solution: Using a sealer material will help improve the adhesiveness. Examples of such surfaces:

Copper Brass Bronze

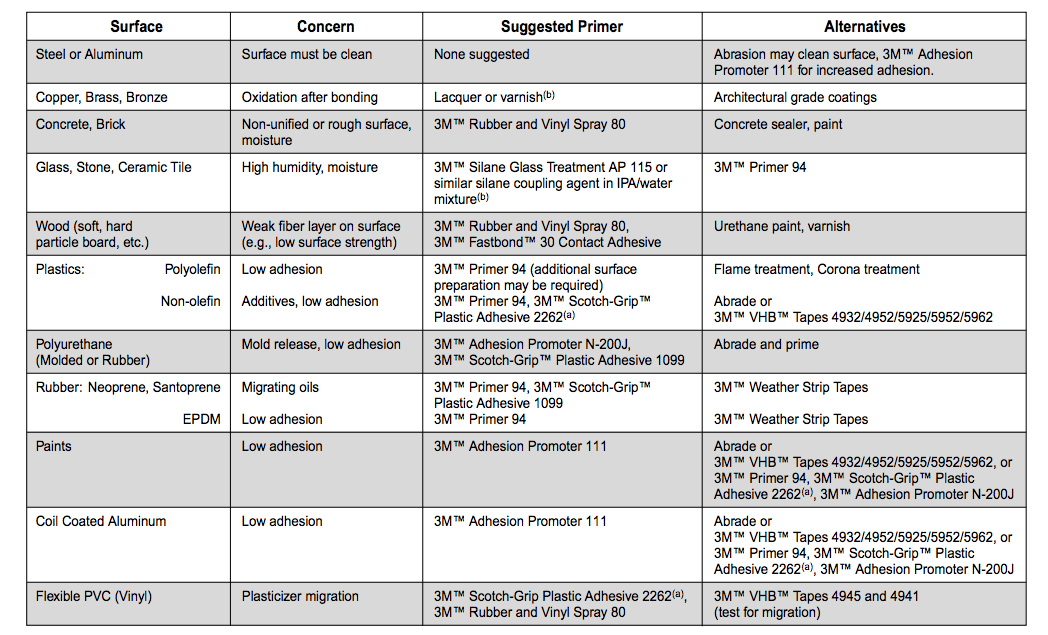

1.6 Priming This is an additional step that you can take to enhance the adhesiveness. By priming a surface, you are essentially creating a new surface to promote better adhesion. However, there is no one-size-fits-all primer. Look at the table below to find out the best primer for different surface.

2. Applying the tape

2.1 Maximise adhesive-to-surface Ratio The greater the adhesive-to-surface contact, the stronger the adhesiveness. To maximise this adhesive-to-surface ratio, you need to apply the sufficient amount of pressure. This will help improve bond strength. The recommended strength is at least 15 psi (100 kPa). Use a roller to roll down the tape. However, if a roller is not at your disposal, I find that using your hand and body weight is enough to apply good amount of pressure.

3. Let it rest

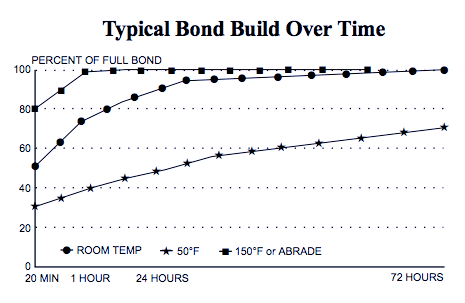

3.1 Don’t rush it After the tape is properly applied, the tape needs time to bond with the surface. Bond strength increases as the adhesive flows onto the surface. Impatient users who did not allow the tape to rest sufficiently will find their tape quickly peeling off. 3.2 Increase the temperature (Optional) The higher the temperature, the faster the tape will reach the ultimate bond strength. To achieve 50% of the maximum bond strength in room temperature, it will take approximately 20 minutes. Below you can see the chart for the correlation between time and temperature to achieve ultimate bond strength. Source: 3M

Conclusion

As you can see, applying the 3M VHB Tape is not straight forward but it is not exactly rocket science. To be frank, if I had not done the research, I would have blamed the adhesiveness problem squarely on the manufacturer. So, the next time your friends complain about their 3M VHB Tape peeling off, send them this article before they go off ranting on the forum about poor build quality.

Where to buy 3M VHB Tape?